![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

|

The FESTO MPS Case-Study

The Festo MPS control application Download This is a CORFU project for the Festo MPS. Copy the MyFesto directory (that is under library and contains the FB types) to the Corfu/library directory. Copy the FestoMPS directory (that contains the Corfu project) under Corfu/projects.

Introduction 1. IEC61499 compliant FB execution environment (RTSJ-AXE) [1], 2. tool infrastructure (CORFU ESS and Archimedes System Platform) [2][3] and 3. development process, the FESTO MPS example application was developed.

The first prototype implementation of the FESTO MPS control application was developed by Evagelia Mpogiatzi in the context of her Diploma thesis [4]. CORFU Engineering Support System (CORFU ESS) was utilized to apply the hybrid approach described in the paper entitled “Using UML in Control and Automation: A Model Driven Approach” by K. Thramboulidis 2nd IEEE International Conference on Industrial Informatics, (INDIN’04), June 2004, Berlin [5].

This case study is also used as a running example in the paper entitled "Design Alternatives in the IEC 61499 Function Block Model" by K. Thramboulidis [ETFA06] [6].

FESTO Modular

Production System

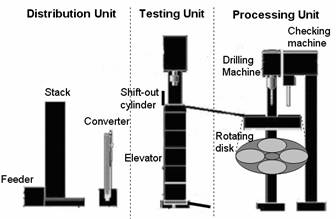

Fig. 1. FESTO Modular Production System (schematic diagram) [6].

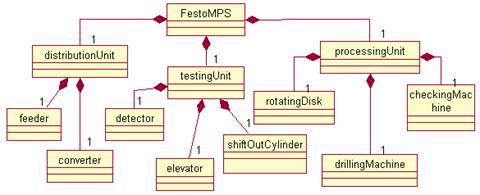

Fig. 2. FESTO MPS composition hierarchy [5]. “The distribution unit, which is composed of a pneumatic feeder and a converter, forwards cylindrical work pieces from the Stack to the Testing unit. The testing unit is composed of the detector, the elevator and the shift out cylinder. The detection unit performs checks on work pieces for height, material type and colour. Work pieces that successfully pass this check are forwarded to the rotating disk of the processing unit, where the drilling of the work piece is performed as the primary processing of this MPS. The result of the drilling operation is next checked by the checking machine and the work piece is forwarded for further processing to another mechanical unit. A detailed description of FESTO MPS can be found in [7] and [8].” [6].

The control

application In the following selected diagrams from the development of the prototype control application of FESTO MPS that is described in [4] are given. Actors (Initiating IPTs) : 1. Operator 2. Converter 3. Elevator 4. DetectionModule 5. Rotating disc

Use case list

|